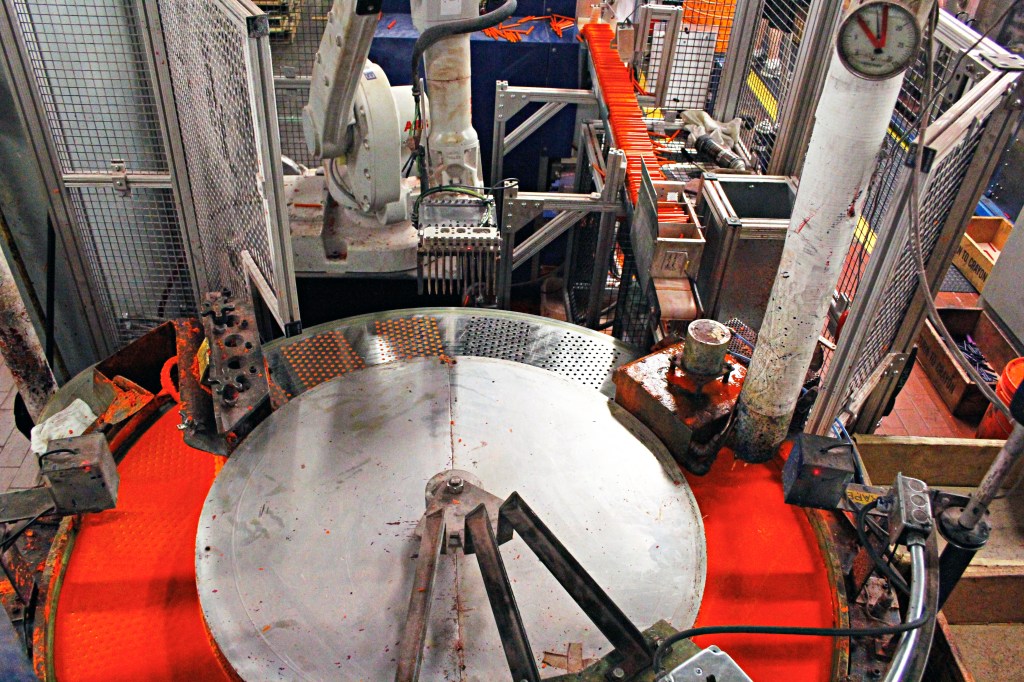

Step into the Crayola factory. It is in Easton, Pennsylvania. Humming machines and busy people are hard at work. Each day, the company makes 13 million crayons. The crayons are used by kids around the world.

“There’s a great demand

demand

EYEJOY—GETTY

the need for something

(noun)

Our stand was successful because of the high demand for lemonade on a summer hot day.

for crayons,” says Elizabeth Rieland. She is an engineer at Crayola. She solves problems. She looks for better and quicker ways to make crayons. “We use automation,” Rieland says. This means using robots and machines to help get the job done.

EYEJOY—GETTY

the need for something

(noun)

Our stand was successful because of the high demand for lemonade on a summer hot day.

for crayons,” says Elizabeth Rieland. She is an engineer at Crayola. She solves problems. She looks for better and quicker ways to make crayons. “We use automation,” Rieland says. This means using robots and machines to help get the job done.

Making Crayons

Heated wax and pigment are poured into molds. The crayons take shape.

WILLIAM THOMAS CAIN—GETTY IMAGES

Crayola makes its crayons in large batches

batch

BRIAN T. EVANS/GETTY IMAGES

an amount of something

(noun)

We baked two batches of brownies.

. They are made of heated wax and pigment, or color. A pipe pours the liquid mixture into molds

mold

BRIAN T. EVANS/GETTY IMAGES

an amount of something

(noun)

We baked two batches of brownies.

. They are made of heated wax and pigment, or color. A pipe pours the liquid mixture into molds

mold

MILANEXPO—GETTY

a container used to shape something that is poured or pressed into it

(noun)

We put wet sand into molds to build a sandcastle.

. The molds form the crayons. The crayons harden as they cool.

MILANEXPO—GETTY

a container used to shape something that is poured or pressed into it

(noun)

We put wet sand into molds to build a sandcastle.

. The molds form the crayons. The crayons harden as they cool.

Next, a machine pushes the crayons out of the molds. Then a robotic arm lifts them. It puts the crayons on a conveyor belt. This moves them to another machine. Its job is to wrap a label around each crayon.

Finally, workers pick up the labeled crayons. They put them in a collator. That’s a special machine. It puts one crayon of each color into boxes. Now boxes of crayons are ready to be sent to stores. Crayola crayons are sold in more than 80 countries.

A worker puts crayons into a collator. It sorts the crayons into boxes.

WILLIAM THOMAS CAIN—GETTY IMAGESRieland is always trying to improve the production process. “Every year, we try to get better at one thing,” Rieland says. “This year, it’s putting crayons into the boxes.”

Rieland also helps name new crayons. Crayola has more than 100 colors. “It’s a fun time to be in the crayon business,” she says.

“Apricot” crayons are labeled by a machine. Each label wraps around a crayon twice.

WILLIAM THOMAS CAIN—GETTY IMAGESA Smart Solution

What happens to imperfect crayons? Inspectors look at them before they are packaged. They gather up the broken and chipped ones. These crayons are sorted by color. Then they are melted. This way, they can become part of another batch of crayons. This method keeps imperfect crayons from going to waste.