Under Construction

Watching a giant robotic arm pour layers of concrete might not sound that exciting. But videos of this process, known as 3D printing, are getting tens of millions of views on social media. They’re giving people a glimpse of a world in which affordable 3D-printed houses are the new normal.

Aiman Hussein has been posting the videos. He’s director of printing technologies at Alquist 3D. Hussein’s most-watched posts show the company’s printers layering row after row of concrete to build up a house’s outer walls. (See “Homes in Hours.”)

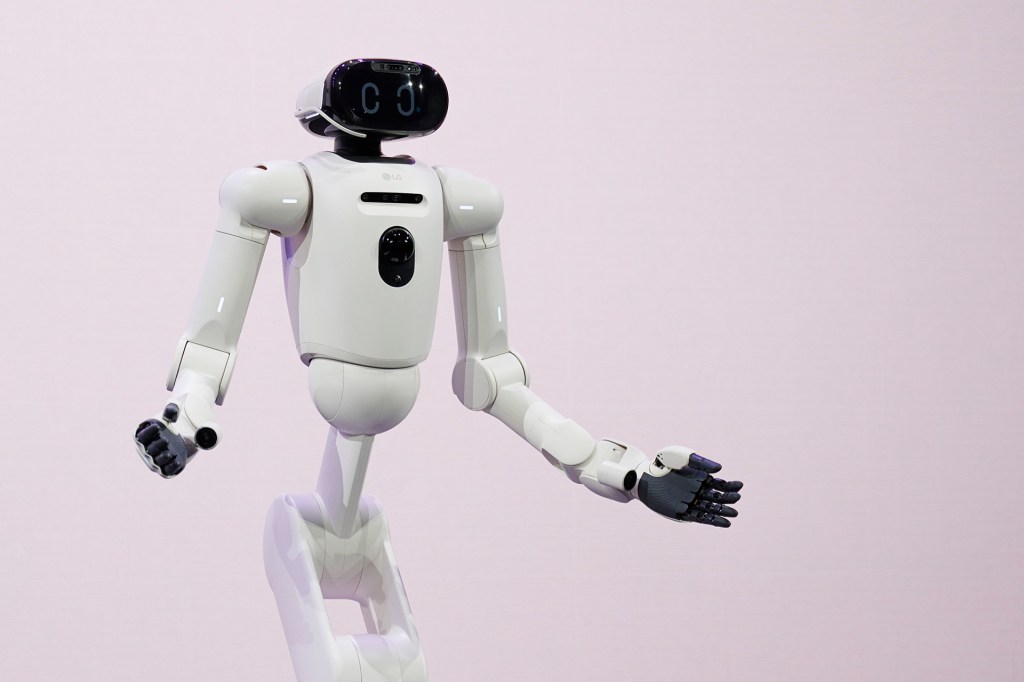

NOW WATCH THIS Videos of 3D-printed home-building are popular on social media. They get people excited about the process.

COURTESY ALQUIST 3DHussein started making videos in order to document the company’s work. But he soon realized something. They were resonating resonate to mean something; to cause an emotional response (verb) The boy's story resonated with his friend, who'd had a similar experience. with people online. Watching them is “oddly satisfying,” he says.

Welcome Home

The idea of 3D-printed houses has been gaining popularity. A survey published by Realtor.com in 2021 found that 66% of consumers would consider living in one. About a third of respondents said they believed 3D printing would replace more-traditional methods of construction.

LAYER BY LAYER An Alquist 3D printer pours concrete layers to construct a wall.

COURTESY ALQUIST 3DIn December 2021, a Virginia family moved into a 3D-printed house. Alquist had built it for Habitat for Humanity’s homebuyer program. “Working with Habitat for Humanity was a fantastic experience,” Hussein says. “It really showed how we can fulfill that mission statement of getting people into homes they can afford.”

MOVE IN Alquist founder Zachary Mannheimer (left) poses with people in front of their new 3D-printed home.

COURTESY ALQUIST 3DZachary Mannheimer is Alquist’s founder and CEO. He says 3D-printed homes cost less than homes made with wood. “Since the [Habitat for Humanity] home was completed and the first story about it came out,” he said last spring, “we’ve been averaging anywhere between 25 and 50 requests for 3D-printed homes per hour. So it has confirmed all our beliefs about why this is so important. The need is huge.”

A BETTER WAY? Home-building is expensive. Alquist says 3D printing lowers costs. This can make homes more affordable.

COURTESY ALQUIST 3DGrowing Pains

According to Mannheimer, the biggest challenge facing the 3D-printed housing industry is scale scale the size or extent of something (noun) Joanne was impressed by the scale of the plan. . “At the moment, [there are fewer] than 10 companies using this technology in America,” he said. “To really make a dent in the affordable-housing crisis, we’d need more like 50.”

Ryan Smith is director of the School of Architecture at the University of Arizona. He agrees that 3D printing could transform the construction industry. But he warns that American labor and supply chains for home-building are set up to handle wood, not concrete. “If you change the means and methods of construction,” Smith says, “you would have to develop a whole workforce around that, to be able to manage it.”

Affordable 3D-printed homes aren’t going mainstream anytime soon. But getting people interested may be the first step. Hussein’s videos “unlock your imagination for what else is possible,” Mannheimer says. “We can excite a whole new generation about building things with computers and machines instead of shovels.”

Homes in Hours

Alquist’s machines are a lot like small 3D printers, but much bigger. Like all 3D printers, Alquist’s have dispensers that pump out layers of material—in this case, concrete—one on top of another.

To build an object, the machines follow a layout. It comes from a digital file. The process can be used to create anything from jewelry to furniture to the walls of a house. The outer part of a house can be built in about 20 to 30 hours.