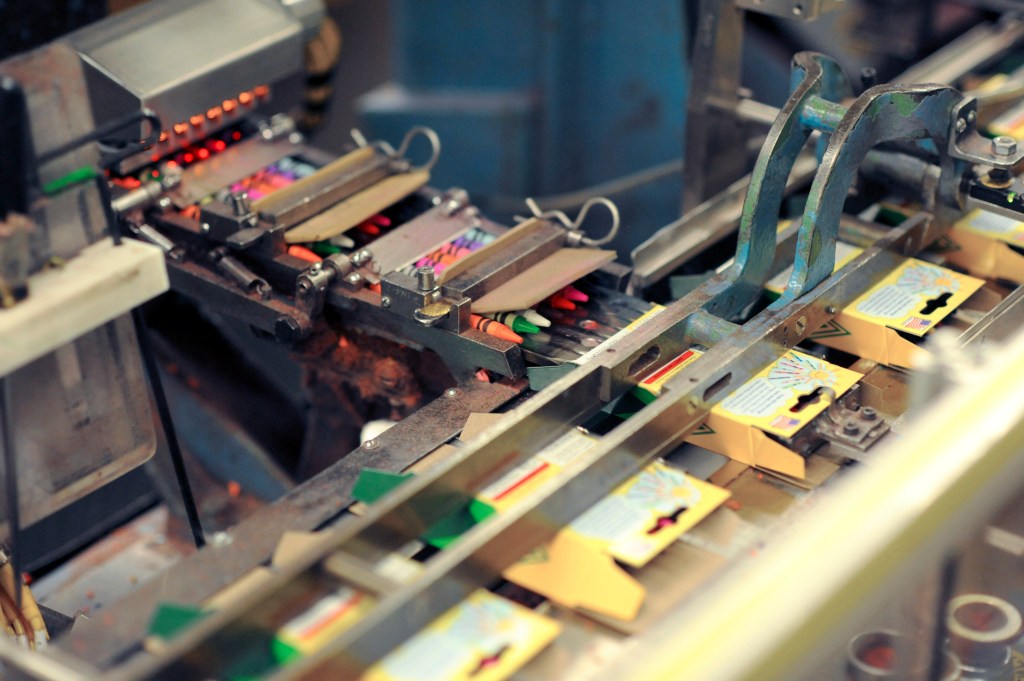

Take a trip to Easton, Pennsylvania. It’s home to the Crayola factory! Crayola makes 13 million crayons every day. People and machines get the job done. Keep reading to learn how crayons are made.

Crayons are made of wax and color. First, the wax must be heated. Then a worker adds a bag of colored powder.

Next, the wax is poured into molds. This forms the crayons. They harden as they cool. A machine pushes them out of the mold.

After that, the crayons are run through a labeling machine. Each label wraps around twice. This makes the crayons stronger. Workers inspect

inspect

CAICIMAGE/TREVOR ADELINE—GETTY IMAGES

to look at something carefully

(verb)

Before buying a used car, you should have a mechanic inspect it.

the crayons. Damaged

damaged

CAICIMAGE/TREVOR ADELINE—GETTY IMAGES

to look at something carefully

(verb)

Before buying a used car, you should have a mechanic inspect it.

the crayons. Damaged

damaged

BRUNNO RAFFA/EYEEM—GETTY IMAGES

harmed or broken

(adjective)

I cannot ride my bicycle because it is damaged.

crayons are set aside.

BRUNNO RAFFA/EYEEM—GETTY IMAGES

harmed or broken

(adjective)

I cannot ride my bicycle because it is damaged.

crayons are set aside.

Then workers pick up the crayons. They put them in a collator

collator

CLIVE STREETER/GETTY IMAGES

a machine that arranges objects in the correct order

(noun)

The fax machine acts as a collator when it places pieces of paper in a certain order.

.

CLIVE STREETER/GETTY IMAGES

a machine that arranges objects in the correct order

(noun)

The fax machine acts as a collator when it places pieces of paper in a certain order.

.

The collator takes one crayon of each color. It puts them into boxes. Now boxes of crayons are ready to be sent to stores. Soon, kids will use the crayons.